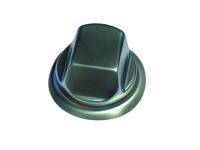

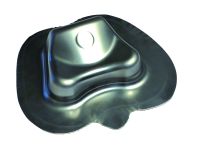

HYDROFORMING

We have various manufacturing processes and machine tools available for the manufacture of individual components and assemblies. Hydroforming is a milestone in sheet metal processing. The aim is to save production steps. We take over the complete production from the CAD drawing to the production of the tools to the finished product.

THE BENEFITS OF HYDROFORMING INCLUDE:

- Prototype parts can be delivered within 4 weeks of receipt of the order and technical clarification.

- Tool cost savings of 80% because only the cavity is required and punches and guides can be dispensed with.

- The realization of complex geometries and free-form surfaces using a single manufacturing process.

- To reduce the forming steps for complex components to one step.

- Time-optimized and cost-effective production options for a diverse range of products.

- The possibilities for processing all cold-formable materials.

- Simple material optimization: a wide variety of materials and different material thicknesses (from 0.05 - 6 mm) can be used in the same tool.

- Aluminum, sheet steel, stainless steel, special steels, titanium, etc. can be formed.

TECHNICAL SPECIFICATIONS:

Part size: max. 1200 x 1200 mm

Shaping depth: max. 450 mm